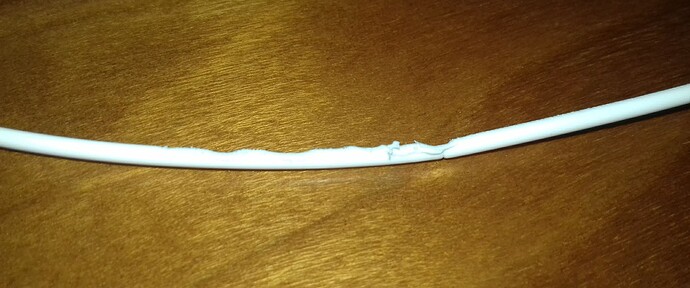

Printer started chewing filament. This meant it was unable to feed it through and therefore nothing was reaching the nozzle. The printer carried on making the movements of the print, but stopped extruding filament.

First thought was a blocked nozzle/hotend, which I checked out (with help from Clogged nozzle/hotend (MINI/MINI+) | Prusa Knowledge Base) and determined was not the problem

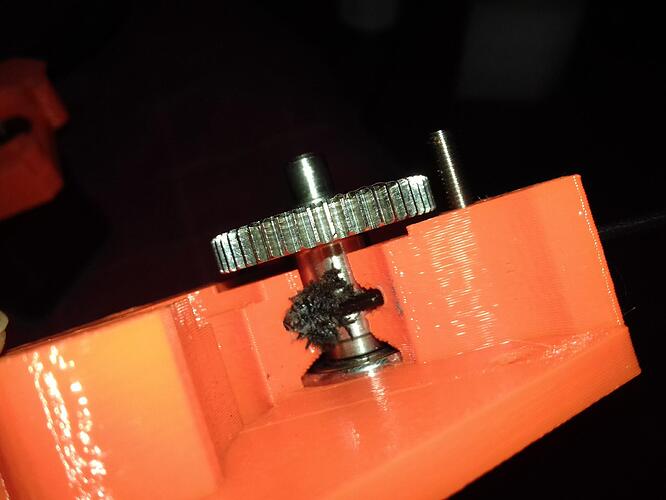

Next checked the extruder pulleys, opening two hatches to have a look. There were signs of filament dust, which I cleared using compressed air, but I wasn’t able to get a good look. (Tried a test print after this and the same thing happened, so the search continued.)

I decided to take the extruder apart to get a proper look at the pulleys, as detailed here:

https://help.prusa3d.com/en/guide/how-to-access-and-clean-the-extruder-pulley-mini-mini_126457

and this revealed a chewed=up chunk of filament that was jamming the pulley.

(In order to reveal this I had to remove the extruder idler screw and cover. I found the extruder assembly intructions for the kit version of the MINI useful when it came to re-assembling!)

Having found the following note I suspect the problem may have been a too-tight idler screw, and have attempted to set it correctly:

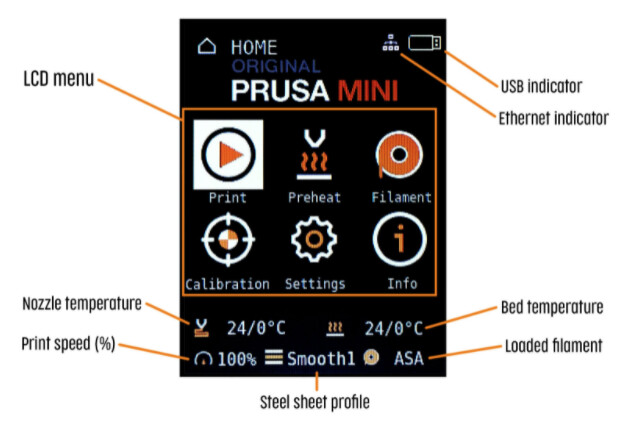

The idler screw is located right below the PTFE tube where you load the filament This adjusts the pressure of the filament onto the filament pulley.

If you find that the extruder filament pulley is full of plastic residue, the idler screw may have been adjusted too tight. It can be adjusted with the 2.5 mm Allen key. The head of the screw should be flush to just within the printed plastic part of the extruder when the filament is not loaded.

(From Clogged nozzle/hotend (MINI/MINI+) | Prusa Knowledge Base )

Test print underway, and fingers crossed …

… Sadly this doesn’t seem to have fixed the problem. But leaving it here as it’s all good info, and we may well need it again